Calcinator Simulations

In the calcination process in industrial cement calciners large amounts of carbon dioxide are emitted. There are two main contributors to this emission:

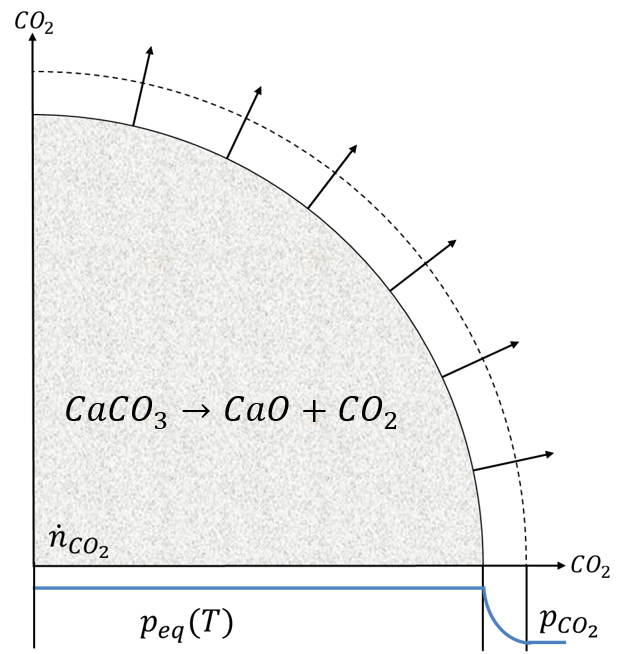

- the decomposition of calcium carbonate CaCO3 to calcium oxide CaO and carbon dioxide CO2,

- the combustion of fuel, which is needed to provide the thermal energy to enable the endothermic calcination reaction.

This emissions could be reduced, if the applied amount of fuel is minimized. To minimize energy consumption while keeping the desired conversion of CaCO3, a detailed process analysis is needed. Computational fluid dynamics (CFD) is a viable tool to get better insight in phenomena in complex flows. Even though computers have become more powerful very rapidly in recent years, it is of interest to keep simulation time short to be able to perform optimisation in reasonable time. A simple reaction and diffusion limited calcination model, based on the porous particle approach, was developed and implemented in the open source CFD-software OpenFOAM®.

Schematic representation of the calcination model.

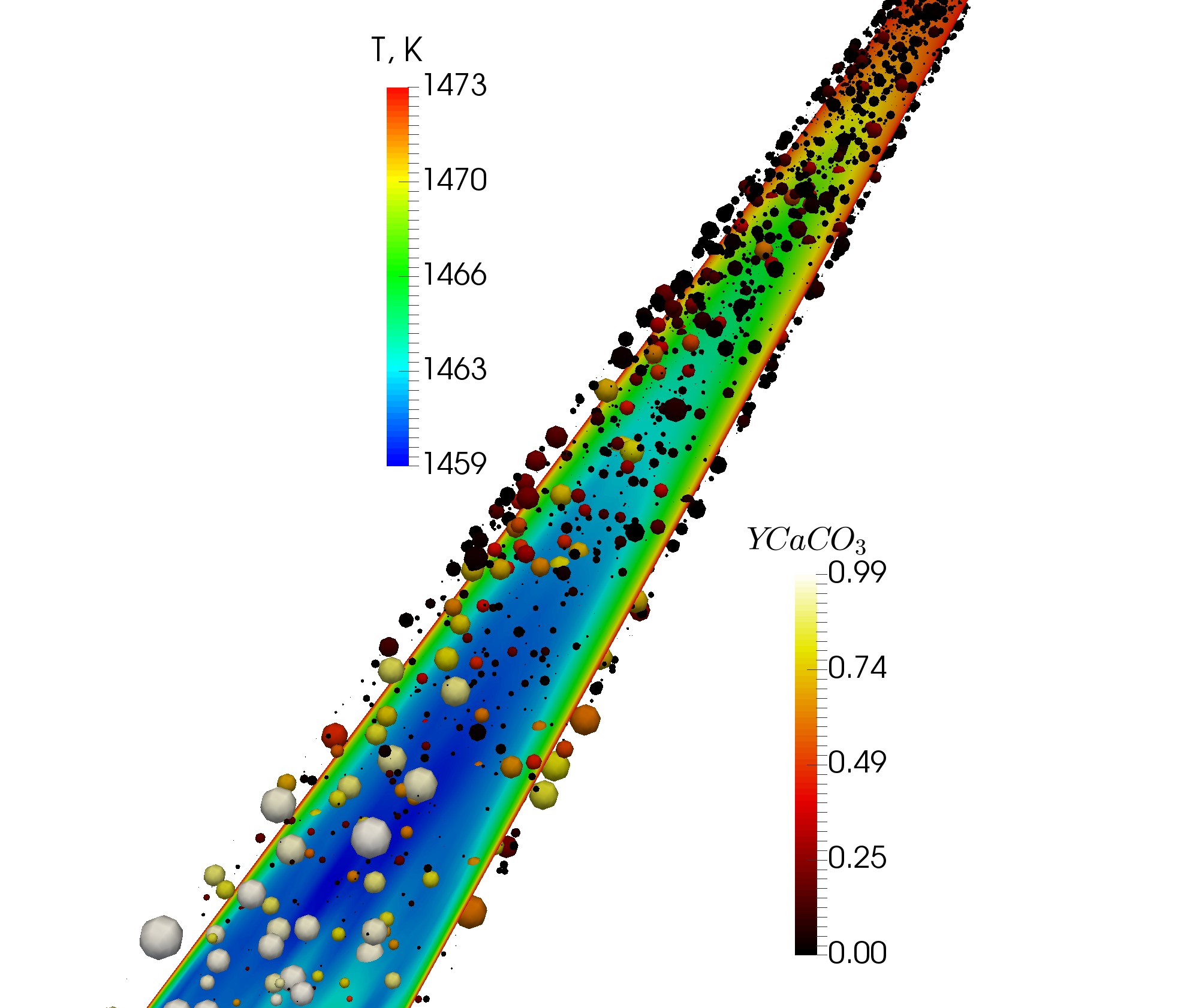

Simulated fluid temperature profile and particle CaCO3 concentration in an isothermal pipe reactor.