Development of stirrer systems which provide optimal mixing behaviour for biogasfermenters and minimize the stirrer energy requiremnt using CFD methods

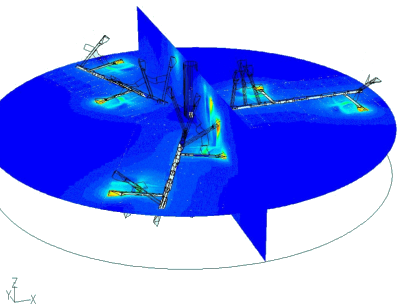

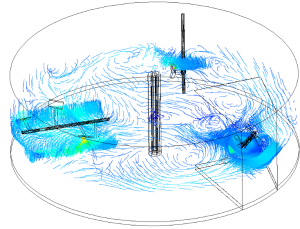

The purpose of this project is the investigation of the mix-behaviour and performance of the agitation systems in biogas plants and to present them through Computational Fluid Dynamics (CFD) simulation. This EDP-tool can model and predict the actual fluid dynamics in a closed system. Thus it may help to plan optimal reactor geometries, position and combination of agitation systems as well as to minimize the energy requirements.

Data from at least two biogas plants with different agitation systems will be collected. The rheologic behaviour of the reactor content will be experimentally studied and described taking in account the different substrates fed to the plant and the resulting particle-size and fiber-length distributions as well as the viscosity. These experimental procedures will be also improved and detailed on the basis of previous experience.

The CFD-models will be tested through Bacillus globigii addition and interpretation of the resulting distribution curves. Modification of these basic models will be performed until predictions for the following problems may be stated:

- Optimization of the mixing-dynamics in existing plants.

- Optimal reactor geometries.

- Minimization of the energetic requirements of the agitation systems.

- Optimal agitation set-up for an agricultural biogas plant.

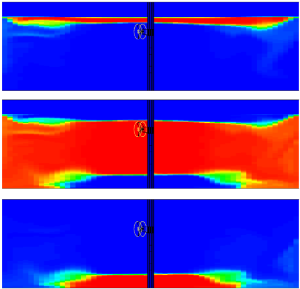

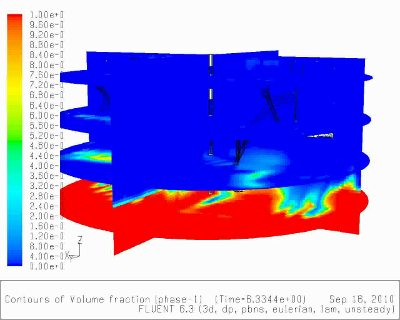

Figures: Left: Streamlines in a biogas fermenter, Right: light, main and heavy phases during intermittent stirrer operation

Transient simulation of a biogas digester with two paddel stirrers and four different phases (5.5MB)