Development of a Macro-Viscosimeter to determine the rheological behaviour of the slurries in biogas digesters and analysis by CFD methods

The aim of this work was to design and calibrate a new type of viscosimeter which is able to measure the rheological properties of slurries uesd in biogas digesters. To optimise the mixing performance of large-scale biogas fermenters using CFD-methods it is necessary to have data that describe the properties of the fluid. Typical slurries contain a large amount of organic and inorganic particles (up to 12 %) with particle sizes and fibre lengths varying in a large range and display a non-Newtonian behaviour. If a fluid contains particles or fibres with a diameter or length scale in the order of the gap size usual viscosimeters fail to produce reliable results. As fluids containing high amounts of fibres have the tendency to settle and deposit, the bob is replaced by a stirrer to assure a homogeneous mixing of the suspended particles. This principle that is used in this work is also called vane-in-a-large-cup-principle. The design of this macro-viscosimeter allows measurements of the rheological properties of fluids which contain particles up to a diameter of 10mm and fibres with a maximum length of 30 mm.

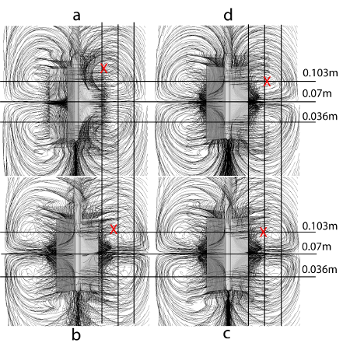

Comparison of the vortices in glycerol (a), Xanthan

0.25 (b), Xanthan 0.35 (c) and Xanthan 0.55 (d)