TOREtech

Aim of this project is to reduce the energy consumption of tunnel kilns in brick industry. This is achieved by replacing conventional burner, which need a significant amount of fresh air for operation, by burner which are using hot kiln gas. The focus of the project is the developement of new pure gas burner based on the jet pump principle. Using state of the art simulation tools (CFD) and experimental techniques (Design of Experiments, cold model, hot model, field tests), they are optimised to reduce the natural gas consumption while keeping a high product quality. The energy consumption can potentially be reduced by 10%, which leads to an according reduction of CO2 emissions.

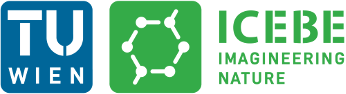

Streamlines showing the pressure distribution for the flow through a brick.

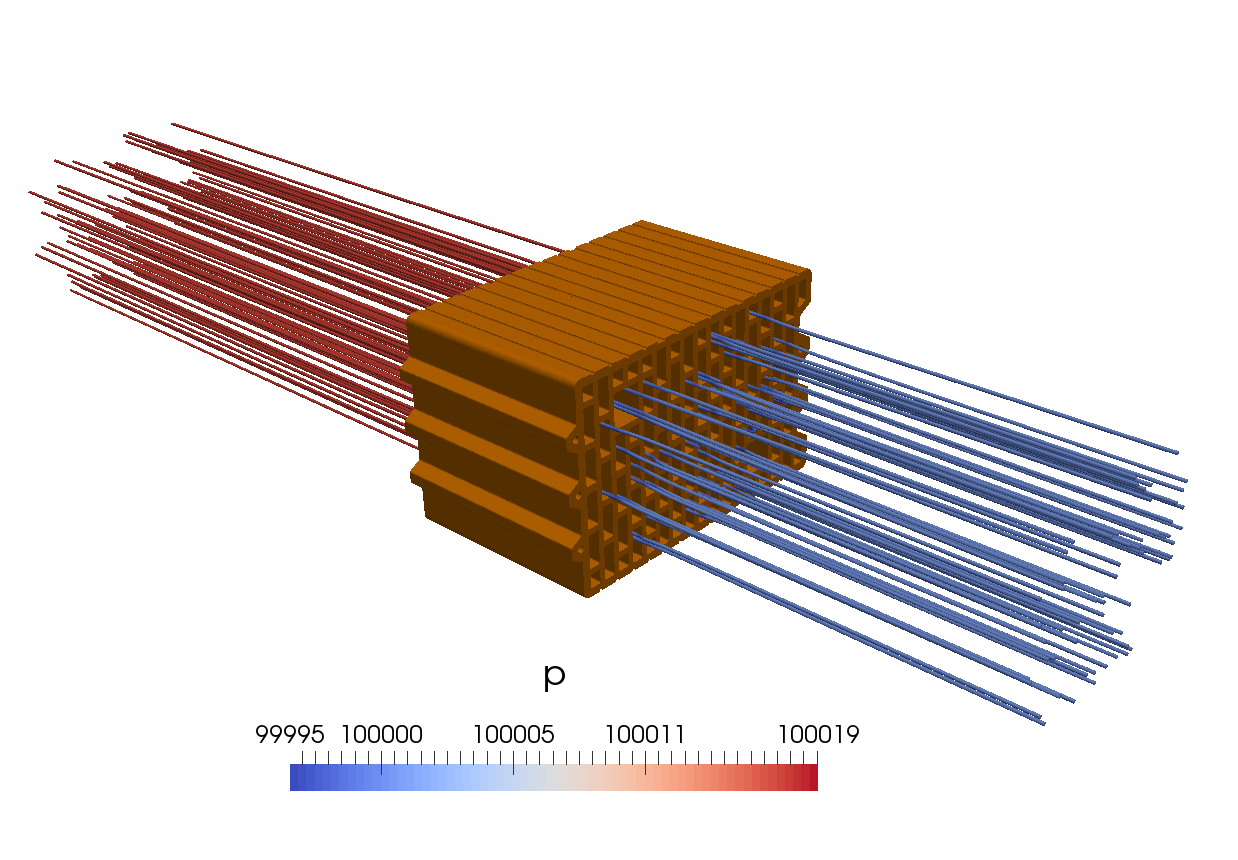

Simulated CO2 concentration and streamlines in the cold model.

Hot model (Wienerberger AG).